Idivayisi yokuphulukisa ye-UV LED

- Model: UVSS-13T

- Various Sizes

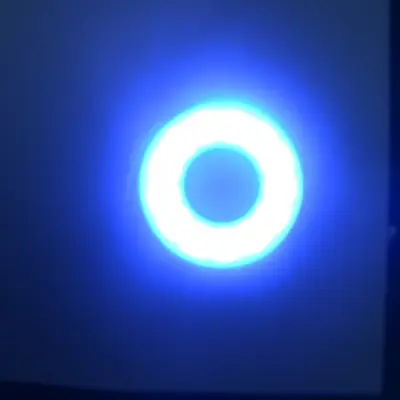

UVET’s UV LED curing device features a ring-type design that delivers uniform UV irradiation across a Φ25–Φ50mm coverage area. Available in three optional wavelengths—365nm, 385nm, 395nm, and 405nm—this curing device is engineered for versatility and precision. It is widely used in electronic assembly, medical device bonding, and applications in the optics and optoelectronics industries, where reliable and consistent curing performance is essential.

Specifications

| Part No. UVSS-13T | Wavelength 365nm, Intensity 1500mW/cm2 |

| Part No. UVSE-13T | Wavelength 385nm, Intensity 2000mW/cm2 |

| Part No. UVSN-13T | Wavelength 395nm, Intensity 2000mW/cm2 |

| Part No. UVSZ-13T | Wavelength 405nm, Intensity 2000mW/cm2 |

| Irradiation Area | Φ25~Φ50mm |

| Heat Dissipation | Water cooling |

-

Descriptions

Idivayisi yokuphulukisa ye-UV LED uhlelo oluhlangene, olusebenzayo kakhulu lohlobo lwendandatho. Inikeza ukukhanya kwe-UV okungaguquguquki nokulawulwa kwephuluki ngokunemba. Ngendawo ye-irradiation ye-Φ25mm kuya ku-Φ50mm kanye nokukhethwa kwe-wavelength ye-365nm, 385nm, 395nm, noma i-405nm, isekela izinto eziningi ezizwela i-UV.

Le divayisi yokuphulukisa isetshenziswa kabanzi ku-elekthronikhi, i-optics, kanye nomhlangano wedivayisi yezokwelapha. Iqinisekisa imiphumela yokuphulukisa ehlanzekile, esheshayo ngokusebenza okuthembekile. Idizayini epholile ngamanzi isiza ukugcina amazinga okushisa aphansi okusebenza, ngisho nangesikhathi sokusebenza isikhathi eside.

Izici

- Indawo ye-irradiation ehlosiwe (Φ25-Φ50mm): Ukukhanya kwe-UV okugxile ekwelapheni okusebenzayo nokunembile

- Izinketho eziningi ze-wavelength (365nm, 385nm, 395nm, 405nm): Ukuhambisana okuguquguqukayo nezinto ezahlukahlukene

- Ukuphathwa okushisayo okupholile kwamanzi: Okukhiphayo okuzinzile ngokulawula ukushisa okusebenzayo

- Ukulawula okusheshayo kokuvula / ukuvala: Akukho sikhathi sokushisa nokunciphisa ukusetshenziswa kwamandla

- I-interface yomsebenzisi-friendly: Kulula ukuyisebenzisa ngokuqeqeshwa okuncane

- Ukushisa okuphansi: Ukuvikela izingxenye ezibucayi nezinto zokwakha

Izinzuzo zezicelo zezimboni

Idivayisi yokuphulukisa ye-UV LED ihambisana nemisebenzi ehlukahlukene yokunemba. Ku-elekthronikhi, isetshenziselwa ukubopha, ukubekwa uphawu kanye nomhlangano omncane. Lezi zinhlelo zokusebenza zizuza ekwelapheni okuthembekile nokunciphisa umthelela wokushisa.

Ekukhiqizeni kwezokwelapha, uhlelo lubopha izingxenye ezinjenge-catheter nezindlu zokuxilonga. Isebenza ngokucophelela nangokuphepha ngezingxenye ezibucayi. Ku-optoelectronics, isiza ukuqondanisa nokuvikela amalensi, izihlungi, nezinzwa. Idivayisi iqinisekisa ngisho nokumbozwa kwe-UV ngaphandle kokulimaza izinto.

Ugongolo lwayo luhlala luzinzile, luvumela ukuphulukiswa okufanayo ezindaweni eziyinkimbinkimbi noma ezinemininingwane. Lokhu kuhambisana kwenza kube kufanelekile izinqubo zokukhiqiza eziphindaphindiwe.

Yini eyenza le divayisi yokuphulukisa ye-UV LED ivelele

Ngokungafani nezinhlelo zendabuko zokuphulukisa, le divayisi eqhutshwa yi-LED isebenza ngokushesha ngaphandle kwesikhathi sokushisa. Ikhiqiza ukushisa okuncane, okuphephile ezintweni ezibucayi. Ngezinketho ezine ze-wavelength, ivumelanisa kalula nezinamathiselo ezahlukahlukene nokumboza.

Ukuhlanganiswa kulula. Ingena eziteshini ze-benchtop noma imigqa ezenzakalelayo ngokusetha okuncane. Noma ngabe isetshenziselwa ukuphulukisa indawo noma ukubopha okuningiliziwe, inikeza isivinini, ukusebenza kahle nokunemba.

Idivayisi yokuphulukisa ye-UV LED nayo isekela ukonga amandla nokugcinwa okuphansi. Isikhathi sayo eside sokuphila kwe-LED nokusebenza okuhlanzekile kunciphisa isikhathi sokuphumula nezindleko zokusebenza.

-

FAQs

Q1: What is a UV LED Curing Device used for in industrial applications?

A: A UV LED Curing Device is used to rapidly cure UV-sensitive adhesives, coatings, and inks in applications such as electronics, medical devices, automotive, and optical assembly.Q2: What are the advantages of using a UV LED Curing Device over traditional UV lamp systems?

A: It offers longer lifespan, lower heat output, energy efficiency, instant on/off control, and is mercury-free, making it safer and more reliable for production.Q3: What wavelengths are supported by the UV LED Curing Device?

A: Common supported wavelengths include 365 nm, 385 nm, 395 nm, and 405 nm, chosen based on the specific chemistry of the UV-curable material.Q4: Can the UV LED Curing Device be integrated into automated production systems?

A: Yes, most devices support PLC connectivity, remote control interfaces, and customizable triggering options for full automation compatibility.Q5: What maintenance is required for the UV LED Curing Device?

A: Maintenance is minimal and typically involves occasional cleaning of optics and air filters, along with periodic checks of LED output for consistent performance.