UV LED ukuphulukisa kuhhavini

- Model: CS180A

- Various Sizes

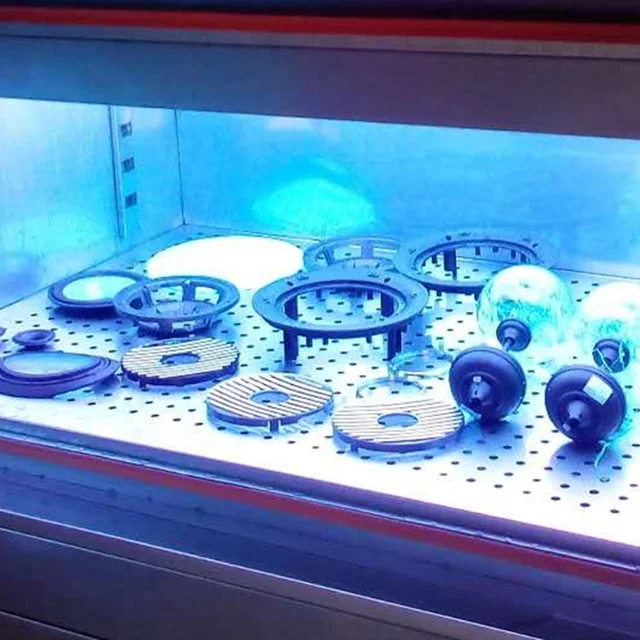

UVET's UV LED curing ovens are available in a variety of sizes and are designed with built-in reflectors to ensure uniform UV exposure for reliable and efficient curing. The system is equipped with high-intensity UV LED lamps with adjustable UV power and working distance to meet various process needs. This curing oven improves production efficiency and supports fast and consistent curing results.

Specifications

| Part No. | CS180A |

| Inside Dimensions | 180(L)x180(W)x180(H) mm |

| Outline Dimensions | 230(L)x230(W)x230(H) mm |

| Working Status | Visible via anti-UV leakage window |

| Operation | Close the door:The UV LED lamp starts working automatically. Open the door during irradiation: The UV LED lamp stops immediately. |

-

Descriptions

I-UV LED Curing Oven isekela izinhlelo zokusebenza ezahlukahlukene zokuphulukisa kufaka phakathi ukubopha, ukubekwa uphawu, nokumbozwa kwezinto ezibonakalayo ezifana namalensi, izihlungi, ama-prism, nemihlangano ye-fiber. Noma ngabe kuhlanganiswe namalebhu amancane noma izindawo zokukhiqiza zevolumu enkulu, i-UV LED yokuphulukisa i-oven inikeza ukusebenza okulinganisiwe ngokunemba nangokungaguquguquki.

Lawa ma-oveni atholakala ngobukhulu begumbi nokwakheka ukuze kuhlangatshezwane nokuhamba komsebenzi okuhlukahlukene kokukhiqiza. Kusuka kuma-benchtop setups we-prototyping kuya ezinhlelweni ezizenzakalelayo ngokuphelele emigqeni yokukhiqiza ephezulu, i-oven ngayinye yokuphulukisa ilungiselelwe ukusatshalaliswa kwe-UV endaweni yokusebenza. Lokhu kuqinisekisa imiphumela ethembekile yokuphulukisa kungakhathalekile i-geometry yengxenye noma ukubekwa.

Isicelo

UV LED Area Curing Lamp for Optics in Lab Materials Research

Izibani zokuphulukisa indawo ye-UV LED zisetshenziswa ngokuyinhloko kumalebhu ocwaningo lwezinto zokwakha, ikakhulukazi ocwaningweni nasekuthuthukisweni kwezingxenye ze-optical. Lezi zibani zivame ukusetshenziselwa ukwelapha nokukhipha ama-glues, ama-adhesives, ukumboza, nezinto ze-elekthronikhi - izinqubo ezithuthukisa izakhiwo zezinto ezibonakalayo futhi zithuthukise ukuthembeka kwama-prototypes namamodeli wokuhlola.

Izinhlelo zokusebenza ezibalulekile:

- Ukuhlolwa kokusebenza: Isetshenziselwa ukuhlola ukuthi izinto zisabela kanjani ekuphulukiseni nasekusetsheni kwe-UV, ukusiza abacwaningi ukuhlola ukusebenza komkhiqizo nokuqina ngaphansi kwezimo ezilawulwayo.

- Imiphumela ephindaphindwayo: Qinisekisa imiphumela engaguquguquki futhi ephindaphindwayo ngesikhathi sokuhlolwa kwephepha noma impahla, ukwenza lula ukuqinisekiswa kokutholakele nokugcina ubuqotho bokuhlola.

- Imvelo Yocwaningo Ephephile: Isekela indawo yelabhoratri ehlanzekile, ezinzile futhi ephephile, enika amandla uphenyo lwesayensi olunemininingwane nolunembile ngaphandle kwezingozi ezihambisana nezinhlelo zendabuko zokuphulukisa.

UV LED Area Curing Lamp in Rapid Prototyping

Izibani zokuphulukisa indawo ye-UV LED zinikeza isisombululo esinamandla se-prototyping esheshayo, ikakhulukazi izingxenye eziphrintiwe ze-3D. Lezi zinhlelo zelapha izinto ngokushesha nangempumelelo, ukuhlolwa nokuqinisekiswa kuthatha isikhathi esincane.

Izinzuzo ezibalulekile:

- Ukuphulukiswa okusheshayo kwezingxenye eziphrintiwe ze-3D: Lezi zibani zisheshisa inqubo yokuqina. Ungahlola futhi uhlole ama-prototypes ngokushesha ngemuva kokuphrinta.

- Ukuhlolwa okuphelele kwe-Prototype: Uhlelo luvumela amaqembu ukuthi ahlole futhi athuthukise ama-iterations amaningi kalula. Lokhu kusiza ukuthuthukisa ukunemba kokwakhiwa nokusebenza.

- Ikhwalithi ethuthukisiwe ngama-Adhesives nama-Sealants: Ukuphulukiswa kwe-UV LED kuqinisa izibopho nezimpawu. Iqinisekisa ukuthi ama-prototypes ahlala isikhathi eside, anokwethenjelwa, futhi alungele ukukhiqizwa.

UV LED Area Curing Lamp in Electronic Component

ProductionIzibani zokuphulukisa indawo ye-UV LED ukuthuthukisa ukukhiqizwa kwezingxenye ze-elekthronikhi. Lezi zinhlelo zelapha izinamathiselo, ama-encapsulants, kanye nokumbozwa komhlaba ngokushesha nangokunembile. Ngenxa yalokho, izingxenye zihlala ziboshelwe ngokuphepha futhi zivikelwe, ziqinisekisa ukusebenza okuthembekile kwesikhathi eside.

Izinzuzo ezibalulekile:

- Ukubekwa Okunembile Kwezinto Ezibonakalayo: Inqubo yokuphulukisa igcina izinamathiselo nama-encapsulants endaweni, ukuvimbela ukushintshwa noma ukusonteka ngesikhathi sokukhiqiza.

- Ukuqina okuthuthukisiwe: Ukuphulukiswa kwe-UV kuqinisa ubuqotho besakhiwo sezingxenye, okukhulisa ukusebenza kwazo futhi kwandisa isikhathi sokuphila kwazo.

- Ikhwalithi Yomhlangano Engaguquguquki: Ukwelashwa okuthembekile kusiza ukugcina amazinga aphezulu omhlangano.

-

FAQs

Q1: What is the purpose of a UV LED curing oven in industrial applications?

A: A UV LED curing oven provides controlled, high-efficiency curing of UV-reactive materials such as adhesives, inks, and coatings.Q2: How does a UV LED curing oven improve upon traditional UV curing systems?

A: Compared to mercury-based systems, UV LED ovens deliver cooler, more energy-efficient curing with instant on/off functionality, longer operational life, and environmentally responsible performance without ozone or hazardous materials.Q3: Which materials are compatible with UV LED curing ovens?

A: These ovens effectively cure a wide range of UV-sensitive materials, including acrylate adhesives, conformal coatings, varnishes, and UV inks on substrates such as plastic, metal, glass, and composites.Q4: What wavelength options are available for UV LED curing ovens?

A: Standard options include 365 nm, 385 nm, 395 nm, and 405 nm, selected to match the photoinitiator chemistry of the UV formulation to ensure consistent, deep, and rapid curing results.Q5: What key features should a high-performance UV LED curing oven offer?

A: Uniform irradiance across the curing zone, precision intensity and exposure control, advanced thermal management (air or water cooling), safety interlocks, and options for PLC or conveyor integration.