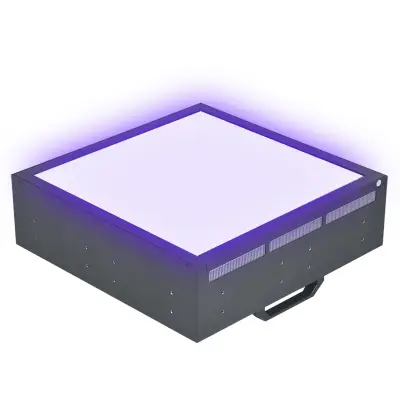

Iphaneli Yokuphulukisa Izikhukhula ze-UV LED

- Model: UVSS-784B3

- Various Sizes

UVET’s UV LED Flood Curing Panel features a large 350×350mm irradiation area, making it ideal for high-throughput curing applications. Equipped with fan cooling for stable and efficient operation, it supports optional wavelengths of 365nm, 385nm, 395nm, and 405nm to suit a variety of materials and processes. This UV LED flood curing panel is perfect for use in electronic assembly, medical device bonding, optical bonding, and the optoelectronics industry, delivering consistent, uniform curing across wide surfaces.

Specifications

| Part No. UVSS-490B3 | Wavelength 365nm, Intensity 750mW/cm2 |

| Part No. UVSE-490B3 | Wavelength 385nm, Intensity 900mW/cm2 |

| Part No. UVSN-490B3 | Wavelength 395nm, Intensity 900mW/cm2 |

| Part No. UVSZ-490B3 | Wavelength 405nm, Intensity 900mW/cm2 |

| Irradiation Area | 350x350mm |

| Heat Dissipation | Fan cooling |

-

Descriptions

Iphaneli yokuphulukisa izikhukhula ze-UV LED inikeza ukwelashwa kwe-UV okusebenzayo futhi okungaguquguquki endaweni ebanzi ye-350mm × 350mm. Ilungele ukucubungula izingxenye ezinkulu noma ukuphulukisa izingxenye eziningana ezincane kumjikelezo owodwa. Lokhu kuyenza ibe yithuluzi elibalulekile ezimbonini ezifana ne-elekthronikhi, i-optics, ukukhiqizwa kwamadivayisi wezokwelapha, kanye ne-optoelectronics.

Uhlelo lunikeza izinketho ezine ze-wavelength-365nm, 385nm, 395nm, ne-405nm-evumela ukuthi ihambisane nezidingo ezahlukahlukene zezinto ezibonakalayo. Ngenxa yalokho, abasebenzisi bangalungisa kahle inqubo yabo yokuphulukisa ngesivinini esihle nekhwalithi yesibopho.

Ngenxa yohlelo lwayo lokupholisa oluhlanganisiwe, iphaneli isebenza ngokuqhubekayo ngaphandle kokushisa ngokweqile. Lokhu kusiza ukugcina ukusebenza kokwelapha okungaguquguquki futhi kwandisa isikhathi sokuphila kwezingxenye zangaphakathi.

Izici

- Ukupholisa okufanelekile kwe-fan: Igcina amazinga okushisa angaphakathi izinzile futhi iqinisekisa ukusebenza okuthembekile ngesikhathi sokusebenza okwandisiwe

- Ukusetha okusheshayo nokulula: Izilawuli ezilula zisiza abasebenzisi ukuthi baqale ngokushesha ngaphandle kokuqeqeshwa okuncane

- Asikho isidingo sokuhlanganisa: Isebenza ngokwayo noma ingena ezinhlelweni zokukhiqiza ezizenzakalelayo ngaphandle kobunzima

Kungani ukhetha i-UV LED Flood Curing Panel?

Lolu hlelo lusekela ukwelashwa okukhulu ngenkathi kugcinwa ukunemba okuphezulu. Indawo yayo yokuphulukisa engu-350mm × ne-350mm ilungele ukwelapha izingxenye ezigcwele noma izinto eziningi ezihlelwe ngamaqoqo. Lokhu kunciphisa inani lokudlula kokwelapha futhi kusheshise ukukhiqizwa.

Ama-wavelengths akhethiwe anikeza ukulawula okwengeziwe kokuthi izinto zilapha kanjani. Ungafanisa ukukhishwa kwe-UV nokunamathela noma ukumboza okusetshenzisiwe. Lokhu kusiza ukuthuthukisa ukunamathela, ikhwalithi yokuqeda, nokuqina kwesikhathi eside.

Iphaneli iqukethe izinzuzo eziyinhloko zobuchwepheshe be-LED. Isebenza ngokushesha, ngaphandle kwesikhathi sokushisa. Iphinde isebenzise ugesi omncane futhi ikhiqiza ukushisa okuncane kakhulu, okusiza ukuvikela izingxenye ezibucayi futhi kwehlise izindleko zamandla.

Yini eyenza ihluke?

- Ukusetshenziswa okuguquguqukayo kuzo zonke izimboni: Isekela umsebenzi wokuphulukisa okuningiliziwe ku-elekthronikhi, ukunakekelwa kwezempilo, ukubopha okubonakalayo, kanye ne-optoelectronics

- Indawo enkulu yokuphulukisa (350mm × 350mm): Iphatha izingxenye ezinkulu noma izingxenye ezincane ezihlanganisiwe kumjikelezo owodwa wokuphulukisa

- Ama-wavelengths we-UV akhethiwe (365nm, 385nm, 395nm, 405nm): Iyahambisana nezinhlobonhlobo zokunamathisela nokugqoka

- Izinzuzo ze-LED: Ukulawula okusheshayo kokuvula / ukuvala, ukusebenza kahle kwamandla, ukushisa okuncane, nempilo ende yesevisi yesondlo esincishisiwe

Iphaneli yokuphulukisa izikhukhula ze-UV LED iyisixazululo esinamandla futhi esiguquguqukayo esivumela ukulinganisa okuqondile nokuphumelelayo kokuphulukiswa kwe-UV.

-

FAQs

Q1: What is a UV LED Flood Curing Panel used for?

A: A UV LED flood curing panel is used to cure UV-sensitive adhesives, coatings, and inks over large, flat surfaces in applications like PCB assembly, screen printing, and optical component processing.Q2: What are the key benefits of using a UV LED Flood Curing Panel?

A: It offers uniform UV intensity across the entire panel area, instant on/off functionality, low heat emission, long LED lifespan, and energy-efficient operation without mercury or ozone production.Q3: What wavelength options are available for the UV LED Flood Curing Panel?

A: Standard wavelengths include 365 nm, 385 nm, 395 nm, and 405 nm, chosen based on the photoinitiator in the UV-curable material and desired curing performance.Q4: Can the UV LED Flood Curing Panel be integrated into an automated production process?

A: Yes, the panel can be integrated with conveyors, robotic systems, and PLC-controlled lines, making it suitable for inline and high-throughput curing environments.Q5: What maintenance is required for the UV LED Flood Curing Panel?

A: Maintenance includes regular cleaning of the optical surface, monitoring of the cooling system (air or water), and periodic output checks to ensure consistent and reliable performance.