Yiziphi izinhlelo zokuphulukisa ezenziwe ngokwezifiso?

Izinhlelo zokuphulukisa ezenziwe ngokwezifiso zimelela ubuchwepheshe obenziwe ngokwezifiso okulindeleke ukuthi buhambisane nemvelo yezidingo zokuphulukisa zezimboni ezahlukahlukene. Ngalesi sikhathi, izinhlelo zikhuthaza ukuguquguquka, ukunemba, nokuzenzakalelayo, ngakho-ke zilungele kakhulu ukukhiqizwa kwanamuhla uma kuqhathaniswa namathuluzi ajwayelekile okuphulukisa.

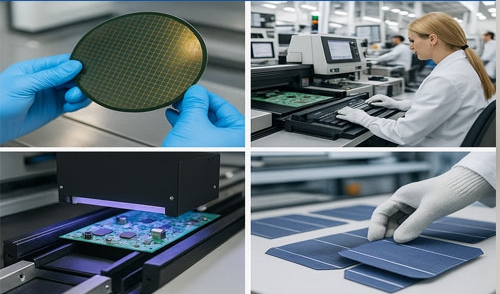

Izindawo lapho izinhlelo zokwelapha ezenziwe ngokwezifiso zingasiza khona zimi kanje:

•Izimboni zokuphrinta- ukufeza imiphumela ecacile futhi egqamile.

•Ukumbozwa nokunamathisela-i-polymerization nokunamathela okungaguquguquki.

• Ukukhiqizwa kwe-elekthronikhi- kuvumela ukuphulukiswa okuphelele kwezingxenye ezibuthakathaka.

• Izimoto kanye ne-aerospace- zithuthukisa ukumbozwa okuhlala isikhathi eside kokusebenza okuphezulu.

Ukuhlanganiswa nokwamukelwa kwe-Automation

Izinhlelo zokuphulukisa ezenziwe ngokwezifiso zingenziwa ngokwezifiso ukuze zilingane ngokuphelele kulayini wamanje wokukhiqiza. Isici se-automation kanye nekhono laso lokulawula nokuguqula inqubo ngesikhathi sangempela sivumela inqubo ukuthi iphulukiswe ngokungaguquguquki, isuse amathuba ephutha lomuntu futhi ikhulise iphesenti lokuthembeka nakakhulu.

UV Tape Curing Systems Agtie Izici Nokusetshenziswa

-

UV

- Tape Curing Wafer Ukucutshungulwa

Ukuphulukiswa kwe-UV tape kuyisinyathelo esidingekayo enqubweni yokusika i-wafer nokugaya emuva, futhi. Itheyiphu ivezwa ekukhanyeni kwe-UV futhi ithathwa futhi iphathwe kalula ngamaphutha ambalwa okuphatha. Lokhu kwenzelwa ukuthi ukuvikelwa kwama-wafers we-semiconductor abucayi kungenziwa ngenkathi futhi isikhathi sokunemba okuphezulu ekukhiqizeni nakho kugcinwa. Njengoba ukubopha itheyiphu kuncipha, amafemu angafinyelela ukuhlukaniswa kwe-chip esebenza kahle kakhulu futhi engaqinisekisiwe.

- Bespoke of Resources

Amateyipu angaphansi kwe-UV dicing angasetshenziswa ezinhlobonhlobo zezinto zokwakha. Zingasetshenziswa futhi engilazini, ubumba, njll., Ngaphezu kwama-wafers e-semiconductor. Lolu hlobo lokuguquguquka lwenza ukuphulukiswa kwe-UV tape kusebenza kakhulu ezimbonini ezahlukahlukene, kuze kufike embonini ye-elekthronikhi, izingxenye zengilazi ngokunemba, nokunye okuningi, futhi kunikeza abakhiqizi inkululeko enkulu nokuqiniseka ekufezeni izidingo zokukhiqiza ezifunwayo.

- Ukwandisa ukukhiqizwa kwenqubo

Imishini yokuphulukisa itheyiphu ye-UV ithuthukisa ukusebenza kahle ekukhiqizeni. Ijubane lokuphendula liyashesha, amazinga okululama angama-suprachronic ayathuthukiswa, futhi isikhathi sokubamba siyancishiswa ohlelweni lonke, ngaleyo ndlela sifinyelele umkhiqizo owengeziwe. Ukukhiqizwa okuthuthukisiwe kusiza abakhiqizi ukuthi bagweme izindleko zokubambezeleka, izinqubo eziyinkimbinkimbi, nokuguquguquka kokusebenza emigqeni yokukhiqiza edinga ukulethwa ngaphakathi komnqamulajuqu omfushane ngaphandle kokuthinta ikhwalithi.

Izinzuzo eziphawulekayo ze-UV Tape Curing

- Ukuthuthukiswa komkhiqizo

Ama-LED e-UV asebenza kahle kakhulu futhi ayashesha ngoba adlula ukuncipha kwezinqubo ngenxa yokunamathela kwetheyiphu, ngoba kuqashwa izindawo zokusakaza ezibandayo. Lokhu kukhulisa ngokuqondile ukudlula futhi kunciphise izikhathi zokuphumula, okusiza abakhiqizi ukuthi babe nokwanda kwenani lemisebenzi eyenziwe.

- Isikhathi esisebenza kahle futhi esinobungani bemvelo

Zibhekwa njengezingozi ezincane kubasebenzi nakwemvelo ngoba izindlela zokusetha itheyiphu ye-UV azikhiqizi i-ozone noma i-mercury. Ukwazi ukunciphisa izinkinga zokulawula kanye nokusiza ezindleleni zokukhiqiza ezinobungani bemvelo, lo mklamo ukhombisile ukuthi unenzuzo ngokweqile.

- Kulula ukuyisebenzisa futhi ukuguquguquka okujwayelekile

Kuma-interfaces wesikrini sokuthinta, imingcele esethwe ngaphambilini yenza inqubo ilawuleke kalula ukuze opharetha bakwazi ukugwema izinselelo ekusingatheni izinyathelo ezahlukahlukene ezihilelekile. Ngaphezu kwalokho, amateyipu nama-wafers angathuthukiswa ngosayizi abahlukahlukene ukuhlangabezana nesidingo sokukhiqiza esinikeziwe, ngakho-ke, isixazululo senziwe ngokwezifiso kakhulu futhi siyaguquguquka.

- Production Line- Curing Machines

Ama-curers we-LED azenzakalelayo anemigqa yokukhiqiza aqinisekisa ukungaguquguquki kwenqubo. Ukungaguquguquki kwekhwalithi nesivinini kunikwe amandla izinzwa ezakhelwe ngaphakathi nezilawuli.

Ukuqonda Kwezobuchwepheshe: Ukusebenza Kwezinhlelo Zokuphulukisa Ezihlosiwe

Izinhlelo zokuphulukisa ezithuthukile zihlanganise ukusetshenziswa kwemithombo yokukhanya ye-UV, imishini ethuthukile, nesoftware ehlakaniphile ukuhlinzeka ngokuphulukiswa okufanele. Ama-wavelengths athile adalwe ngamadivayisi wokuphulukisa we-UV LED asetshenziselwa ukudala i-polymerization ye-coatings kanye nama-adhesives, noma ama-inks. Iqiniso eliphawulekayo lobuchwepheshe yile:

- Ukukhethwa kwe-Wavelength: Izinto ezihlukahlukene kufanele zilaphekwe ngama-wavelengths ahlukene. Izinhlelo ezisetshenziswa namuhla zihlala engxenyeni yebanga le-365-405nm, ngaleyo ndlela zivumelanisa nezinto eziningana.

- Ukulawula Ukuqina: Amandla angalawulwa, angavumela ukwelapha ngaphandle kokulimala kwezinto ngesikhathi esifushane.

- Isikhathi Sokuvezwa: Ukuphazamiseka okuphezulu kanye nokulinganisela kokuchayeka kunikezwa ngokuchayeka okufushane nokunembile.

- Ukuphathwa Kwezinga Lokushisa: Ama-LED akhiqiza ukushisa okuncane, okufana nezibani zendabuko, ngaleyo ndlela kuqeda ukubhujiswa kwawo ngokushisa.

Indawo yokugcina yohlelo olufanele lokuphulukisa olwenziwe

ngezifisoUkunakekelwa kufanele futhi kuthathwe ekukhetheni uhlelo lokuphulukisa olulungiselelwe oluzonciphisa ngempumelelo izindleko zokukhiqiza zebhizinisi futhi lukhiqize umsebenzi wekhwalithi. Isinqumo kufanele senziwe ngosizo lwezici ezithile ezibalulekile, okumele zihambisane nezidingo zomkhakha.

1. Izidingo Zomkhakha

Ukwelashwa okudingekayo kuyahlukahluka phakathi kwezimboni. Kokubili ukuphrinta nokumboza, kanye nokunamathisela kudinga inani elifanele lokuqina kokwelapha, ubude be-wavelength, nesikhathi sokuvezwa. Uhlelo olungakhethwa ikakhulukazi yimboni luzoholela emiphumeleni ezinzile kanye nokuchithwa kwezinto ezimbalwa.

2. Umthamo wokukhiqiza

Into esemqoka - izinga ukukhiqizwa. Njengoba ukusetshenziswa kwezinhlelo zejubane eliphakeme kunezinga elikhulu futhi izinhlelo zokwelapha ezisheshayo zikhona, ukudlula kungakhuphuka ngaphandle kokuyekethisa izinga lekhwalithi. Ngokwezinga elithile, imisebenzi emincane ingasebenzisa izinhlelo eziguquguqukayo neziguquguqukayo ezishintshwa kalula kusetshenziswa amanye osayizi be-batch.

3. Ukuhambisana kwezinto ezibonakalayo

Akuzona zonke izinto ezisebenza ngendlela efanayo ekwelapheni i-UV. I-polymer, ukumboza, kanye nokwelashwa kweglue kungadinga ukuthi kusetshenziswe ama-wavelengths e-UV afanelana kuphela. Uhlelo oluguquguqukayo lwe-wavelength nokuqina lungayenza ihambisane nazo zonke izinto.

4. Ukusebenza kahle kwamandla

Izinhlelo zokusebenza zamandla zonga izindleko zombili imvelo kanye nemithelela yemvelo. Izindlela zokukhanyisa ze-UV LED zidla amandla amancane uma kuqhathaniswa nezibani ezijwayelekile ze-mercury futhi zikhiqiza imiphumela esheshayo futhi ekhiqizwayo.

5. Izinga lokuzenzekelayo

Izinhlelo ezidinga umsebenzi omncane, kufaka phakathi izehlakalo ezimbalwa zephutha lomuntu, zinzima kakhulu ziyaziwa ukuthi zizenzekelayo kakhulu. Amadivayisi asebenza kahle futhi anokwethenjelwa ngoba anezibonisi zesikrini sokuthinta, imingcele eguquguqukayo, kanye nokuqapha kwesikhathi sangempela.

Njengoba kucatshangelwa lezi zici ezingenhla, abakhiqizi bangakhetha inketho yohlelo lokuphulukisa ngokwezifiso olubanikeza izici ezithile ezifana ukukhiqiza okuphezulu, ukufana kwekhwalithi, nokwenza lula ukusebenza okusebenzayo.

Isiphetho

Ukukhiqizwa kwezimboni zesikhathi esizayo kwenziwa ngokwezifiso ukuphulukisa. Abakhiqizi bangase babe nokusebenza kahle kakhulu, bathembeke kakhulu, futhi baguquguquke nge-Tailored Curing Systems eyakhelwe ngaphakathi, uhlelo lokuphulukisa oluzenzakalelayo lwe-LED, nemishini yokulawula ngokunemba kwekhwalithi ephezulu. Ukubambisana nomlingani ofana UVET kuzoqinisekisa indlela eyingqayizivele yokubhekana nenkinga yokwelapha nokunamathela okuphezulu kwezidingo zokukhiqiza kwakho. Imigqa yokukhiqiza incike emisha, ekukhiqizeni, nasekusimeni, okutholakala kuphela ngokutshalwa kwezimali kwisisombululo somuntu ngamunye.