Kuyini ukucubungula i-wafer UV?

Ukucubungula i-Wafer UV kuyindlela yokukhiqiza i-semiconductor esebenzisa i-UV ngesikhathi se-photolithography, ukuhlanza, ukuguqulwa komhlaba, nokubopha. Ezinye izinhlelo ze-UV zigxile ekuhlinzekeni ngemisebe ngezikhathi ezibucayi zenqubo, ukuqinisekisa ukunemba nokwethenjelwa kwesinyathelo ngasinye. Ngokungafani namasu okushisa namakhemikhali, le ndlela ikhetha ukuhlanza okuthuthukisiwe kwe-UV nokubopha ezindaweni ezihambisanayo.

Wafer Processing and Bonding Done with UV Light Could

Ukubeka ungqimba oluyinkimbinkimbi phezu kobuso be-wafer photolithographically

Nge-photolithography, amaphethini athuthukile afakwa ebusweni be-wafer ngesikhathi sokusebenza okulandelanayo, futhi ukususwa kutholakala ngezinyathelo ezincane njengama-nanometer ambalwa.

Izinqubo ezenziwa ngaphandle kokusebenzisa ukushisa

Izinto ezizwela izinga lokushisa njengezibuko ze-GaAs nezinye izinhlanganisela ezibucayi zimi ekuphathweni okungenakucindezeleka njengokuchayeka kwe-UV.

Ukuhlanza nokuguqulwa kwendawo

Ngesikhathi sokulungiselela izingqimba zokumboza noma izingqimba zesibopho, ukuhlanza kwe-UV kungakhubaza izindawo ngokusika amaketanga ekhabhoni okuholela ezindaweni ezingenakungcola.

Ukusimama kanye ne-Eco-friendly Innovations

Amathuluzi okuvezwa kwe-silicon wafer avela esizukulwaneni sokugcina asebenzisa amadivaysi asebenzisa mercury-free ultraviolet LED ubuchwepheshe. Lawa madivayisi anobungani bemvelo ngenxa yokusetshenziswa kwawo kwamandla aphansi kanye nesikhathi sokuphila isikhathi eside.

Imisebenzi esemqoka ye-UV ekucubunguleni i-wafer

I-UV Photolithography

Ukuqopha izici ezincane ne-nano kuma-wafers ne-DUV lithography inekhono elikhulu lokunciphisa usayizi owengeziwe.

Ukubopha kwe-UV Wafer

Isebenzisa izinamathiselo ze-ultraviolet emazingeni okushisa aphansi kakhulu, okudingekayo kubuchwepheshe be-WLP ne-MEMS, ukubopha ama-wafers.

I-UV Assisted Etching ne-Dicing

Inikeza ukubhalwa kwe-silicon, isafire, ne-glass wafers usebenzisa ama-laser e-UV ukuthuthukisa ikhwalithi onqenqemeni ngenkathi kuncishiswa imfucumfucu nokwenza ngcono ukunemba.

Surface Activation

Ukwehla kwamandla okunamathisela kanye namandla angaphezulu ngokwanda kwamandla we-interfacial kubangela ukuqiniswa kwesibopho sokunamathisela.

I-Post Exposure Bake (PEB)

Izinqubo zokuvezwa kwe-post-exposure ku-photoresist ziqinisa ukuxhumanisa izibopho, ukuqinisa incazelo yesithombe nokwenza ngcono ukunamathela namandla jikelele.

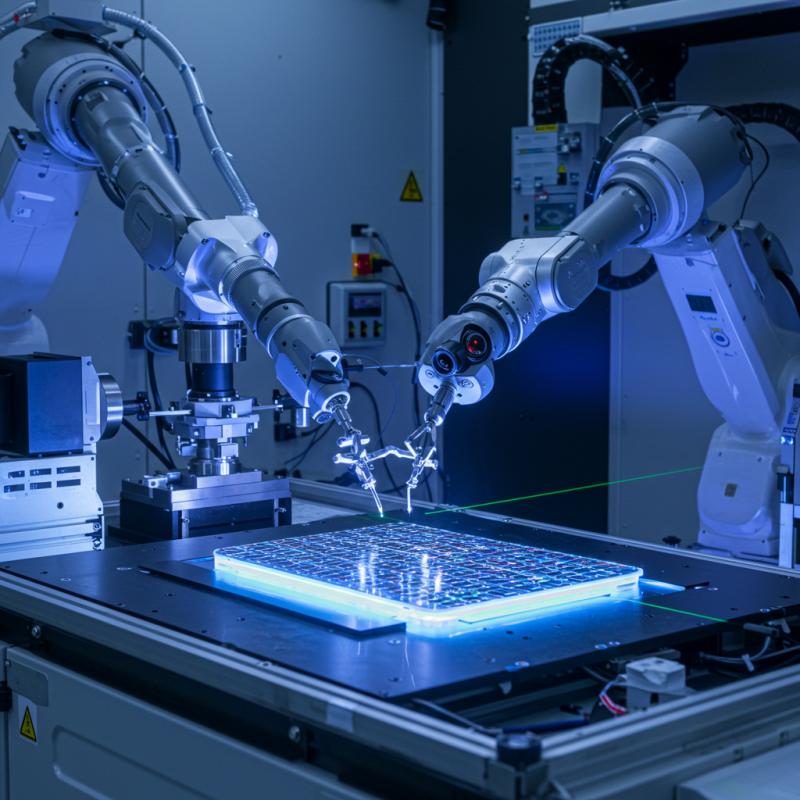

Ukuchayeka Kwezobuchwepheshe: Izinhlelo ze-UV Ezisetshenziswa Ekucubunguleni I-Wafer

Njenganoma yiliphi elinye ithuluzi elisetshenziswa emkhakheni we-semiconductor, izinhlelo ze-UV ezisetshenziselwa ukucubungula i-wafer zidinga ukunemba, ukuthembeka, nokuhambisana nemvelo. Bahlanganisa kokubili i-UV ejulile (185 nm) kanye ne-UV eduze-(405 nm) ngaphezu kokudlula umkhawulo wokuvezwa we-20 W / cm ^ 2 odingekayo kumasu anamuhla we-lithographic kanye nezinqubo eziphambili zokuhlanza ezomile, ukubopha kanye nezinqubo ze-etching.

Uma kuqhathaniswa nama-lasers nama-steppers, ama-aligners wemaski anezindlela ezihlukile zokuvezwa kwe-UV wafer. Lezi zinhlelo zicubungula i-silicon, i-GaAs, ingilazi, ne-sapphire wafers, zihlinzeka ngokulawulwa kokushisa okusebenzayo nokusebenzayo, futhi zivimbele ukushisa ngokweqile ngokuphathwa kokushisa.

Imithombo yemisebe ye-UV, kokubili engasebenzi futhi esebenzayo, ihlukile komunye nomunye ngokuqina kwayo kanye ne-spectrum. Lezi zinhlelo zilungele amayunithi we-R &D kanye nemigqa yokukhiqiza ezenzakalelayo nezenzakalelayo ngenxa yamakhono abo okuzenzekelayo noma agcwele.

Yiziphi izinzuzo ngaphezu kwendabuko?

Uma ubheka izinzuzo zokucubungula amanzi i-UV futhi uyiqhathanisa nezindlela zendabuko ezishisayo noma zamakhemikhali, kuyacaca ukuthi izinzuzo zidlula ububi. Okokuqala, ukucubungula i-UV WAFE kuthuthukisa amasu akhona we-micro- ne-nano-fabrication. Ukuhlanganiswa nezinhlelo ze-UV photolithography kuthuthukisa ukunemba okuhlanganisiwe okutholwe ngezincazelo zephethini eziyinkimbinkimbi.

- Ukuphulukisa mpo nokuveza izinhlelo ze-UV kukhulisa ukudlula ngenkathi kubhekana nezingqinamba zesikhathi somjikelezo. Ngakolunye uhlangothi, lokhu kunciphisa isikhathi sokungasebenzi njengoba ukusebenza kahle kokukhiqiza kukhuphuka futhi kuthuthukise amamethrikhi wokukhiqiza we-volumetric.

- Njengoba lezi zinhlelo zingadingi ukushintshwa kwama-bulb amaningi, ukugcinwa nokuphila kokusebenza kwezinhlelo ze-UV ezisuselwa ku-bulb kuyanda. Lapho lezi zinhlelo zisetshenziswa kanye nokusetshenziswa kwamandla aphansi, ziyakwazi ukonga okuphezulu nokuqhubekayo.

- Njengoba izinhlelo zanamuhla ze-eco-friendly zisahlobene nemithelela ephansi yengozi, ukususwa kwe-mercury namanye amakhemikhali ayingozi kwenza lezi zinhlelo zibe luhlaza. Futhi, imisebe yokushisa ephansi ekhiqizwa yilezi zinhlelo ze-ultraclean izibeka ngaphansi kwemikhawulo yokuzwela yama-wafers angalimazwa ukushisa.

- Ukuncipha kokuthembela kukugeza kwamakhemikhali okumanzi nakho kuthuthukisa ukuhlanzeka kwenqubo futhi kuholele ekuvuneni okuhlanzekile.

Ukwelashwa kwe-Ultraviolet Kwezinto Nezinto

Ama-wafers e-Silicon - Awusizo kakhulu kumasekethe ahlanganisiwe kanye namadivayisi we-MEMS.

I-Gallium Arsenide (GaAs) - Isetshenziswa ezinhlelweni zomsakazo kanye ne-photonic.

Izibuko nama-silicas ahlanganisiwe - Isetshenziswe kumadivayisi we-optical, ama-biosensors, nobunye ubuchwepheshe obuhambisanayo.

I-Polymer Substrates - Isetshenziswa ngaphakathi kwe-elekthronikhi eguquguqukayo.

Ama-Photoresists - Kuyadingeka ezinqubweni ze-heliographic ne-lithographic.

I-Photolithography ku-MEMS ne-IC Technologies

Ku-MEMS, ngokulawulwa kwe-ultraviolet, manje kungenzeka ukuklama nokukhiqiza imishayo ye-nanoscale ehamba ngokunemba, izinzwa, ngisho nama-actuators. Kubuchwepheshe besifunda obuhlanganisiwe, ama-photomasks anezingqimba eziningi akhiqizwa yi-lithography ejulile ye-UV ethambile. Ngesikhathi senqubo ye-urethane polymerization yama-photopolymers, i-diepoxy resins, eyaziwa nangokuthi i-die swell, ithuthukisa ukubopha kwezingqimba ze-dielectric nensimbi, okuthuthukisa ukunamathela kwe-dielectric nensimbi.

Amakamelo okuhlanza kanye ne-automation

Imiklamo ye-ISO yekilasi elihlanzekile ihlanganiswe nezici ezintsha ezizenzakalelayo; ngaphezu kwalokho, imingcele yohlelo lokucubungula i-UV wafer iyanda. Izinhlelo zihlinzeka:

- Ukukhishwa kwentuthu okuzenzakalelayo okuzenzakalelayo kokuhlanganiswa okungaphazanyiswa, okuqhubekayo kwe-wafer.

- Izixhumanisi zephaneli yokuthinta.

- Ukunikezwa okuqhubekayo nokukhishwa okuphansi kwezinhlayiya zokuvikela kunciphisa ukungcoliswa komoya.

- Idizayini yesakhiwo se-Modular sokulinganisa kancane kancane umthamo wokukhiqiza.

- Ukukhishwa okuphansi kwezinhlayiya ezingcolisayo.

Umhlahlandlela Womthengi: Ukukhetha Uhlelo Oluhle Kakhulu Lokucubungula I-UV Wafer

Ukukhetha i-wafer ye-UV efanele kuzocwenga ijubane, ukunemba nokusebenza kahle kwenkampani ye-semiconductor. Ukucatshangelwa okubaluleke kakhulu ngesikhathi sokukhetha kuhlanganisa:

• Ububanzi be-Wavelengths

Qinisekisa ukuthi ama-photoresists kanye nama-bonding agents asetshenzisiwe anezinhlobonhlobo ze-UV ze-185-405nm.

• Ukuqina kokulawula ukuvezwa kwesistimu

Qinisekisa ukuthi amapharamitha ahlukahlukene futhi asethwe ngaphambilini anezilungiselelo ezihleliwe zokuqina nokulawulwa komthamo oqondile.

• Izindlela zokupholisa

Esebenzayo (uketshezi / umoya) kanye ne-passive (i-heatsink) kufanele inikeze ukuvikelwa okwanele kokushisa ngokweqile ngezikhathi zokusebenza ezinde zokusebenza.

• Scalability

Ucwaningo nentuthuko iqala ngamayunithi e-benchtop aqhubekela phambili ezinhlelweni ze-inline zokukhiqiza ivolumu ephezulu. Izinhlelo ezenziwe ngokwezifiso zamayunithi alungiselelwe ukukhiqiza zakhiwe ngezidingo ezithile.

• Ukuhambisana ne-automation

Hlola izikhala ngeziphathi zamarobhothi, ama-conveyors, kanye ne-automation yegumbi elihlanzekile lezinye izixhumanisi zezinhlelo ngaphandle kwengozi yezikhala ku-interface ezenzakalelayo.

Usizo oluvela kubalingani nabathengisi bemishini yesondlo

Ukulungiswa kwezinto nokusekelwa kwesevisi, ukuthola usizo olufike ngesikhathi kuyaziswa kakhulu ngabathengisi. I-UVET ayinakuqhathaniswa ekuhlinzekeni ngesivinini esiphezulu, i-eco-friendly, i-state-of-the-art cleanroom ehambisana nezinhlelo zokucubungula i-UV wafer ze-semiconductors. Lezi zinhlelo zithenjwa kahle onjiniyela be-semiconductor emhlabeni wonke ngenxa yokuthembela kwijubane nokunemba kwezinhlelo.

Isiphetho

Njengoba ivolumu yokukhiqiza ikhuphuka, isidingo sokucubungula i-semiconductor UV siyanda. Izinzuzo ezinikezwe ukukhanya kwe-ultraviolet ekukhiqizeni ama-semiconductors ukuthuthukiswa komsebenzi oqondile nokulinganisa okungabizi ngendlela ehlanzekile. Lokhu kunemba kutholakala ngesibopho esisizwa ukukhanya kanye ne-etch tiered wafer fabrication. Ufuna ukuthuthukisa ukunemba kokukhiqizwa kwakho? Ubuchwepheshe obunqenqemeni bukulindile ku-UVET, lapho ukunemba komkhakha okungenakuqhathaniswa kutholakala khona nganoma yisiphi isakhiwo songqimba lwe-UV wafer system.